Master Ski Tuning: A Complete Guide to Faster, Smoother, and Safer Skiing

Quick Guide

Let's get one thing straight right off the bat. If you're just dragging your skis out of the garage, brushing off the cobwebs, and heading straight to the lift, you're leaving a huge amount of performance on the table. And I'm not just talking about going a bit faster. I'm talking about control, safety, and the pure joy of a ski that does exactly what you ask it to do. That's what real ski tuning is about. It's not some mysterious black magic practiced only by grizzled old technicians in mountain shops. It's a fundamental part of owning skis, like changing the oil in your car.

I learned this the hard way. Years ago, I spent a small fortune on a pair of high-performance skis, convinced they would transform me into a better skier. The first day out, on bulletproof ice in the East, they felt terrifying. Every turn was a fight, a sketchy slide towards the trees. I blamed the skis, the conditions, my technique. Then a friend took one look at my edges. "Dude," he said, holding up a fingernail to the steel, "these are as round as a spoon. You're basically skiing on two butter knives." A quick session with a file and a wax iron later, and it was like I had a completely different pair of skis. The connection to the snow was instant. That's when I became a believer.

Think of ski tuning as regular health check-ups for your gear. Neglect it, and performance suffers. Do it right, and every run feels more responsive, more fun, and frankly, a lot safer.

Why Bother? The Real Reasons Ski Tuning Matters

You might think wax is just for speed and edges are just for ice. It's way more nuanced than that. Proper maintenance touches every single aspect of your day on the mountain.

- Performance You Can Feel: This is the big one. Sharp edges bite into hard snow, giving you confidence to carve. A well-waxed base reduces friction, so you glide effortlessly between turns and on flats instead of feeling sticky.

- Your Safety is on the Line: This is rarely talked about enough. Dull edges can't hold on steep, hard terrain. They can slip out unexpectedly in a turn. Consistent edge grip is a primary safety feature, not a luxury. The National Safety Council emphasizes equipment maintenance as a key part of injury prevention in any sport, and skiing is no different.

- It Saves You Money (Seriously): A dry base isn't just slow; it's vulnerable. When the P-Tex base material gets dry, it becomes brittle and absorbs dirt. This leads to more and deeper scratches. Deep scratches need a base grind to fix, which costs $40-$60 at a shop and removes precious base material. Regular waxing keeps the base hydrated and resilient, acting like moisturizer for your skis. It's cheaper to prevent damage than to repair it.

- Longevity of Your Investment: Good skis aren't cheap. Regular ski maintenance protects that investment. You prevent rust on edges, delamination, and base damage that can shorten your ski's life by years.

A quick personal rant: The worst advice I ever got was "just ski more, the snow will sharpen your edges." That's like saying driving your car will sharpen the brake rotors. It does the opposite. Skiing on abrasive snow, rocks, and man-made stuff actively dulls and damages your equipment. You have to actively maintain.

The Core Pillars of a Tune: Wax, Edges, and Base

Every ski tune, from a quick refresh to a full overhaul, revolves around three things. Understanding what each one does is half the battle.

1. Waxing: It's Not Just About Speed

Wax gets all the glory for making skis fast, but its primary job is protection. The base of your ski is porous. When it's dry, it sucks up moisture and dirt like a sponge. Wax fills those pores, creating a smooth, hydrophobic surface.

How often? A hot wax every 3-4 days of skiing is a good rule for recreational skiers. Racers do it daily. If your bases look white and chalky, you're way overdue.

Choosing wax can feel overwhelming. Here's a simplified breakdown:

| Snow Temperature | Wax Color (General Guide) | Best For | My Personal Take |

|---|---|---|---|

| Very Cold (Below 14°F / -10°C) | Blue, Purple, Green | Hard, dry snow; early morning corduroy; icy conditions | These are harder waxes. They can be finicky to scrape if you let them cool too much. |

| Cold (15°F to 30°F / -9°C to -1°C) | Red, Blue-Red Hybrid | The most common "all-around" range for many resorts | This is my desert island wax. A good red covers about 70% of my skiing days. |

| Warm (31°F to 38°F / 0°C to 3°C) | Yellow, Orange, Red-Yellow | Wet, slushy spring snow; man-made snow | Softer waxes. They don't last as long but are magic in sticky spring conditions. |

| Very Warm/Wet (Above 38°F / 3°C) | Specialist "slush" waxes, often clear or pink | True spring slush, corn snow, wet powder | Honestly, I often just use a warm universal wax unless it's a real slushfest. |

You can go deep into fluorocarbon vs. hydrocarbon, powders, and overlays, but for 95% of us, a temperature-specific hydrocarbon wax is perfect. The International Ski Federation (FIS) has incredibly detailed material on ski preparation for competition, which shows you how complex it can get at the highest level.

2. Edges: Your Connection to the Snow

If wax is the soul, edges are the bones. They're the literal metal that bites. A proper edge tune has two parts: sharpening and de-tuning.

Sharpening (Side Edge & Base Edge): This is about creating a sharp, consistent angle along the length of the ski. The side edge is the vertical part you see. The base edge is the horizontal part where the base and edge meet. Most recreational skiers do great with a side edge angle between 87 and 90 degrees. A lower number (like 87) means a sharper, more aggressive edge for hard snow. A higher number (like 90) is more forgiving and durable for mixed conditions.

De-tuning: This is the secret sauce most people miss. You don't want your tips and tails razor-sharp. A super sharp tip will "hook" or grab unexpectedly when you're not on edge, making the ski feel twitchy and hard to pivot. You intentionally dull the edge for about 2-4 inches from the tip and 4-6 inches from the tail. A gummi stone or a gentle pass with a fine file does the trick.

Let's be honest, a dull edge on hardpack is just asking for trouble.

3. Base Structure & Repair

Look closely at your base. See those tiny grooves or patterns? That's the structure. It's usually put in with a grinding stone at the factory or a shop. Its job is to channel water and air from under the ski, reducing suction on wet snow. For most skiers, maintaining the existing structure with a good brushing after waxing is enough.

Base repair is for when you get core shots or deep gouges. That's when you clean the wound, melt in a P-Tex candle (or use a drip stick), and scrape it flat. It's satisfying work, like fixing a dent in your car.

The Step-by-Step: How to Tune Your Skis at Home

Alright, let's get our hands dirty. Here's my personal workflow for a full, at-home ski tuning session. You don't need a fancy workshop. A clean bench in the garage works fine.

Pro Tip Before You Start: Always clean your bases first! Use a dedicated base cleaner or isopropyl alcohol to remove old wax, dirt, and grime. Tuning over dirt just grinds it into your ski.

Step 1: Visual Inspection and Cleaning

Lay the skis on a flat surface. Look for major base damage, rust on edges, and delamination. Feel the edges with your fingernail. Are they sharp or rounded? Wipe everything down with cleaner. This is your diagnostic phase.

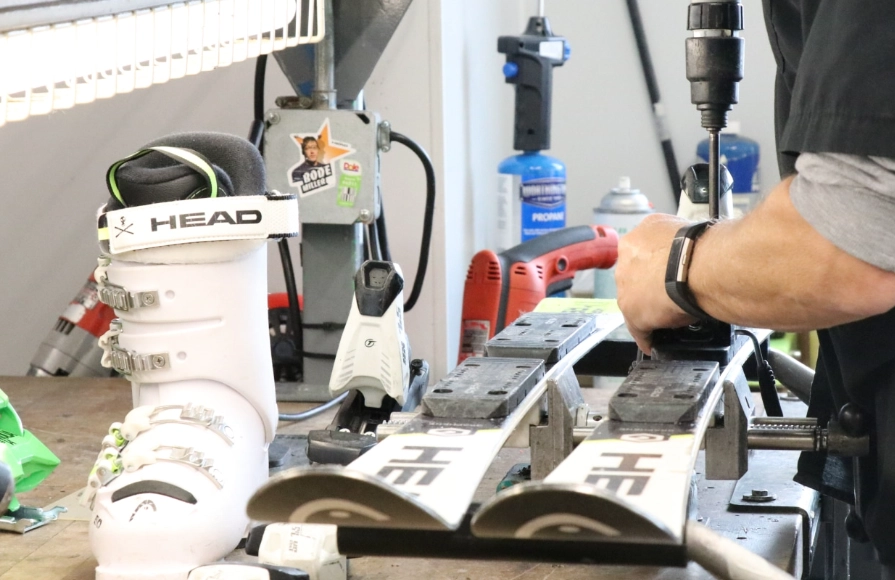

Step 2: Edge Sharpening (The Methodical Part)

Secure the ski in a vise. Start with a medium-grit diamond file (around 400 grit) to set your angle. Use a guide to keep it consistent. I use a 88-degree side edge guide. Make smooth, full-length passes from tip to tail until you feel a consistent burr along the entire edge. Don't press too hard. Let the file do the work. Then, switch to a fine-grit file (600 grit or higher) to polish it out and remove the burr. A few light passes are enough.

Step 3: De-Tuning (The Easy Part)

Take a gummi stone or a fine ceramic stone. Lightly run it along the edge at the tip and tail areas mentioned earlier. You're not removing metal, just knocking off the sharp, grabby corner. You should be able to run your finger over it without getting cut.

Step 4: Waxing (The Fun/Smelly Part)

Plug in your waxing iron. Set it to the temp recommended on your wax. CRITICAL: The iron should melt the wax, not smoke it. Hold the wax bar to the iron and let it drip along the base in a zig-zag pattern. Then, using the iron, smoothly and quickly melt and spread the wax into a thin, even layer over the entire base. Don't let the iron sit in one spot—you can delaminate the ski! Once the whole base is coated, let the skis cool completely. Overnight is best.

Step 5: Scraping and Brushing (The Arm Workout)

Use a plastic scraper. Hold it firmly at a slight angle and scrape from tip to tail, removing all the hardened wax from the surface. You should see the base structure reappear. This takes effort. Then, use a series of brushes: a stiff nylon brush first to open the structure, then a softer horsehair or brass brush to polish. Brushing is what makes the wax job fast and clean.

My first time waxing, I used a clothes iron. Big mistake. It was too hot, had steam holes, and I nearly ruined the bases. Just spend the $50 on a proper waxing iron. It's a non-negotiable tool.

Tools of the Trade: What You Really Need to Start

You can spend thousands, but you can start effectively for under $200. Here's my "Essential" vs. "Nice-to-Have" list.

The Essential Starter Kit:

- Ski Vise: Holds the ski steady. Get one that clamps to a table.

- Waxing Iron: Not a clothes iron. A dedicated ski wax iron with temperature control.

- Plastic Scraper & Scraper Sharpener: A dull scraper is useless.

- All-Temperature Wax: A good red or universal wax to learn with.

- Diamond File Set: A combo pack with coarse, medium, and fine grits (e.g., 220, 400, 600).

- Edge Guide (88 or 90 degree): For consistent edge angles.

- Nylon & Horsehair Brushes: For post-wax cleanup.

- Base Cleaner: Isopropyl alcohol in a spray bottle works in a pinch.

Nice-to-Have Upgrades:

- Rotary Brush & Power Tool Adapter: Saves your arms on brushing day.

- True Bar: Checks if your ski base is flat. Important if you ski a lot or race.

- P-Tex Candles & Metal Grip: For repairing deep gouges that hit the edge.

- Wax Remover (for deep cleans): More effective than base cleaner for stripping old layers.

For sourcing tools and understanding material safety, the Occupational Safety and Health Administration (OSHA) website has guidelines on workshop safety, which is good to keep in mind when dealing with sharp metals and hot irons.

Answering Your Ski Tuning Questions

Here are the things people actually ask me, either on the chairlift or online.

When to DIY and When to Go Pro

I do 90% of my tuning at home. But there are times I happily hand my skis to a good shop.

- Do It Yourself: Regular hot waxes, minor edge sharpening, de-tuning, filling small scratches, seasonal storage prep.

- Go to a Pro Shop: Major base grinds to restore structure, fixing deep core shots that expose the core material, significant edge repair (like a big burr or dent), flattening a badly warped base, or any work involving binding mounting or adjustment. A shop with certified technicians, often following standards from organizations like the Professional Ski Instructors of America (PSIA) or similar national bodies, brings a level of precision and liability coverage you can't match at home.

Knowing your limits is part of being a good ski tuner.

Knowing your limits is part of being a good ski tuner.Wrapping It Up: The Tuned Mindset

Learning how to tune skis isn't just about the mechanical steps. It changes how you think about skiing. You start to feel subtle changes in the snow and know what your skis need. You notice when the edges start to go, or when the wax has worn off. It turns you from a passive passenger into an active pilot.

It's also incredibly satisfying. There's a quiet pride in laying down a perfect carve on a run you prepped for yourself. The money you save is just a bonus. The real payoff is in every confident turn, every effortless glide, and knowing that your gear is ready for whatever the mountain throws at you.

Start simple. Get the iron, the vise, and one bar of wax. Try it. Mess it up. Learn from it. Your skis—and your skiing—will thank you for it.

Leave A Comment